10. December | Folding Boxes | Cutting die | Whitepaper

Maximum reliability when stripping? No problem ...

Maximum safety in the stripping process

Conventional stripping with bottom pins is very time-consuming and provides only limited functionality at high speeds.

The Marbach solutions are known as marbastrip and masterstrip|plate. Individually matching your requirements, these technologies ensure maximum machine speeds and safety in the stripping process …

Sometimes it is the detail that leads to high performance. For example, stripping is no longer a problem with the Marbach marbastrip and masterstrip|plate solutions. No waste, no reduced machine speeds – and it has been that way for many years.

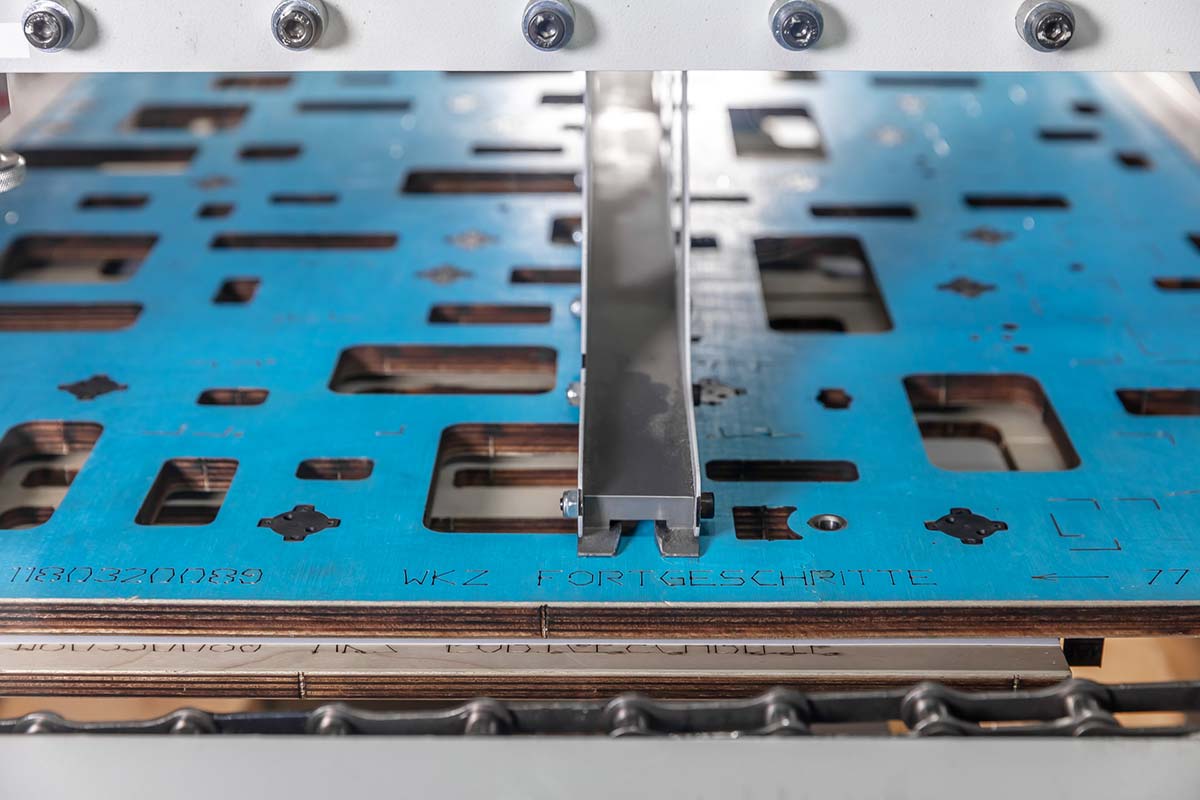

The difference between conventional stripping and stripping with Marbach solutions lies in the specially produced stripping claws. They ensure that the waste is forced through the female stripper during the stripping process – absolutely reliably. This enables machines to run at maximum speed. A straightforward solution which is highly effective, as it makes processes safe, predictable and efficient.

The standard: marbastrip

No more intricate setting of bottom pins; simply install the marbastrip tool in the stripping station and away you go. Dynamic stripping is smoothly implemented with marbastrip. Its design and construction bring success. Marbach has thus created a standard which has been used around 500,000 times worldwide.

High-performance tool: masterstrip|plate

Marbach has developed the masterstrip|plate high-performance tool based on the marbastrip system. The difference here lies in the male stripper. In the masterstrip|plate, it is fitted with a presser plate and special sheet lifters. The presser plate fixes the waste securely and evenly during the stripping process. The sheet lifters – in short, marbafly – support the smooth transportation of the cardboard sheet. Associated with these is the marbapoint set-up aid. Its laser ensures that the female and male parts are quickly, easily and accurately positioned in the diecutter. Overall, this results in a smoothly operating system.

MAKE AN APPOINTMENT

Video Chat with our experts

Select date and time and chat with one of our experts.

Make an appointment