11. August | Corrugated board | Cutting die

Moisture fluctuations when die-cutting corrugated board? No problem!

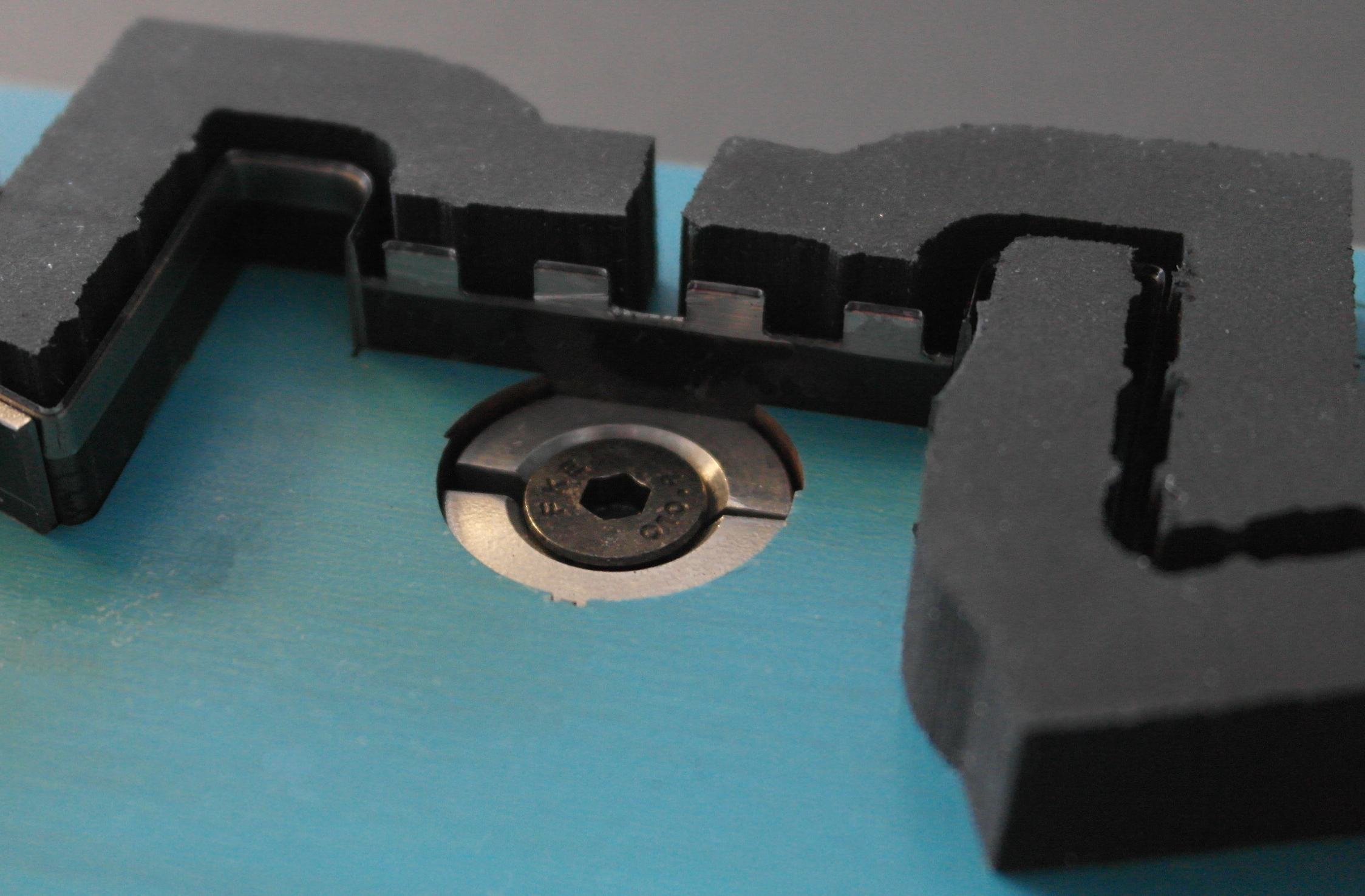

With the nick changing system.

When die-cutting corrugated board, moisture fluctuations make life difficult for machine operators. This is because significantly more nicks are required for dry material than for moist material.

We have the solution to this commonplace challenge: With the nick changing system, your tool can be quickly and flexibly adapted to the respective material properties.

Maximum flexibility when die-cutting corrugated board.

When die-cutting packaging from corrugated board, there are many factors that influence the die-cutting result. One important factor is the moisture content of the corrugated board to be die-cut. In practice, this often varies greatly depending on the type of corrugated board used and how long it has been stored after production. Depending on the condition of the material, therefore, a different number of nicks is required.

The moisture content of corrugated board at the time of processing is an important factor that influences the die-cutting result and the quality of the corrugated board packaging produced. According to the guideline of the VdW (Association of the Corrugated Board Industry), a relative humidity of 55% is optimal. The right time frame between corrugated board production and die-cutting on the processing machine plays a key role here. If this is too long, there is a risk that the material will be too dry. This affects the die-cutting process and the quality of the produced corrugated board packaging, as well as the number of nicks required in the tool. Unfortunately, in practice, it is not always possible to perfectly control the processing time of the corrugated board. Therefore, another solution is needed to absorb the moisture fluctuations that occur.

For this purpose, we have an uncomplicated solution for this in our portfolio: The nick changing system. This enables the user to react quickly and easily to changing properties of the die-cut material. This is done by exchanging rule parts that are provided with nicks. In this way, the cutting-die is always perfectly matched to the respective material. But the nick changing system has other advantages as well: It not only means a shorter start-up time on the machine, but also greater hygiene during die-cutting. This is because its use means that there is no need for subsequent grinding of the nicks in the tool – and thus dust formation that is transferred to the blank can be prevented. In addition, the mechanical lock of the nick changing system also allows multiple rule changes without any loss of clamping.

The nick changing system – for maximum flexibility in the production of your corrugated board packaging.

MAKE AN APPOINTMENT

Video Chat with our experts

Select date and time and chat with one of our experts.

Make an appointment